Props

Reliable and high-capacity support systems for formwork construction, produced with precision and efficiency.

Formwork Props

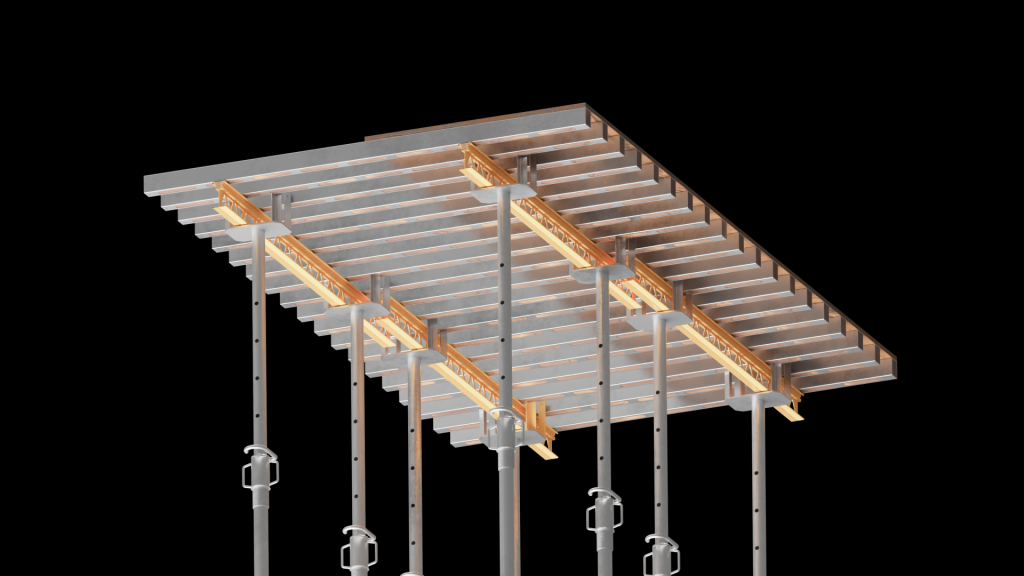

Props are adjustable vertical supports that ensure stability and load-bearing capacity in construction projects.

Overview Props are essential components in construction, providing crucial vertical support to structures. These telescopic steel or aluminum supports are highly adjustable, making them suitable for various applications. They help maintain structural integrity and load-bearing capacity throughout different phases of construction.

Benefits - Load-Bearing: Props effectively support heavy loads, ensuring structural stability. - Adjustable: The telescopic design allows for precise height adjustments, accommodating diverse construction requirements. - Versatile: Props can be used in formwork, scaffolding, and shoring systems. Safety: These supports play a pivotal role in ensuring the safety of workers and the durability of the structure.

Uses Props serve a vital function in construction, ensuring stability and safety by supporting structural elements such as slabs and beams. They are versatile tools widely used in formwork systems, scaffolding, and shoring structures.

Production Capacity

Our state-of-the-art machinery is well-equipped to efficiently produce formwork props. With a daily manufacturing capacity of 500 props during a single shift, we ensure high-quality and timely production to meet your construction needs.

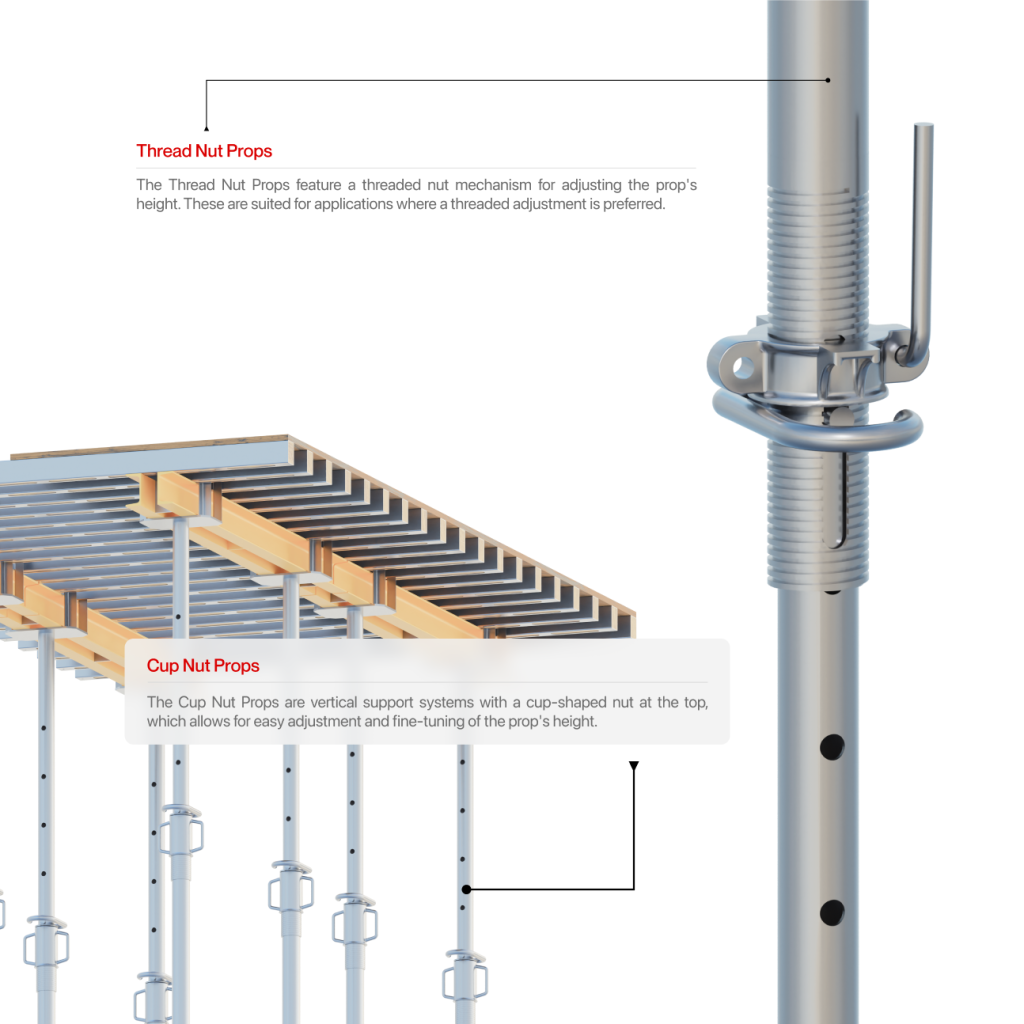

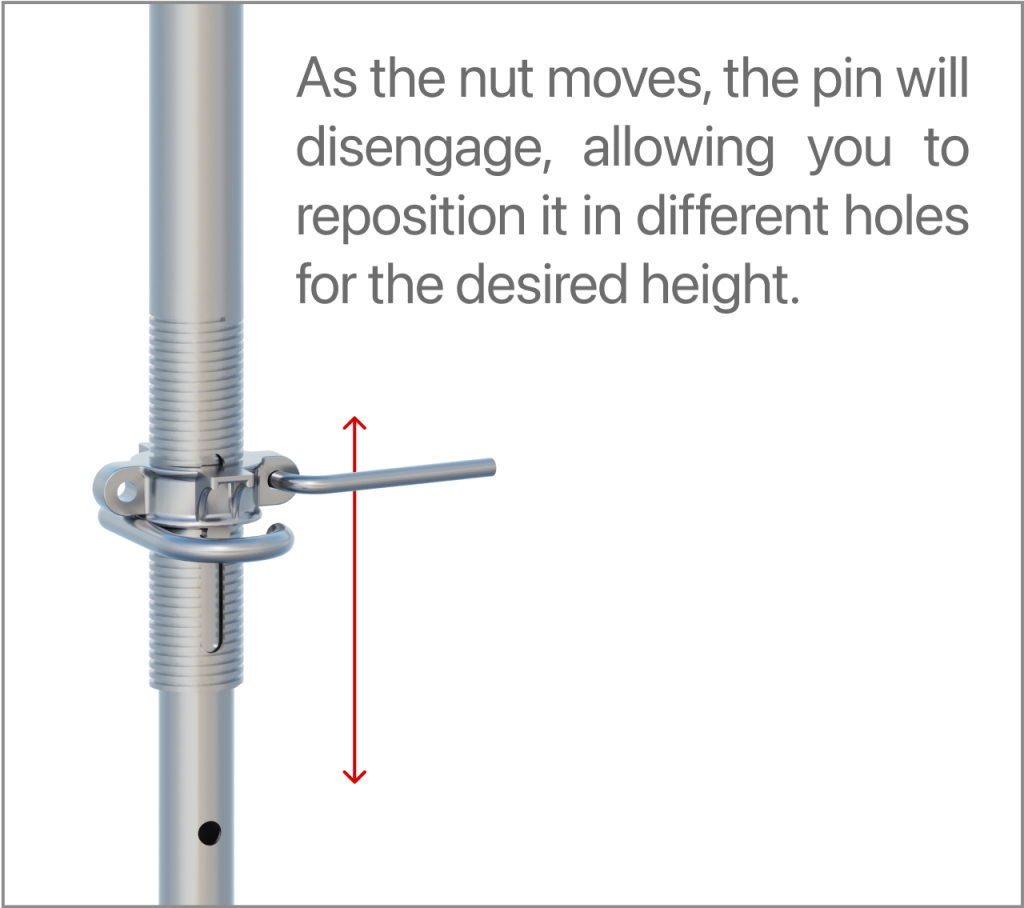

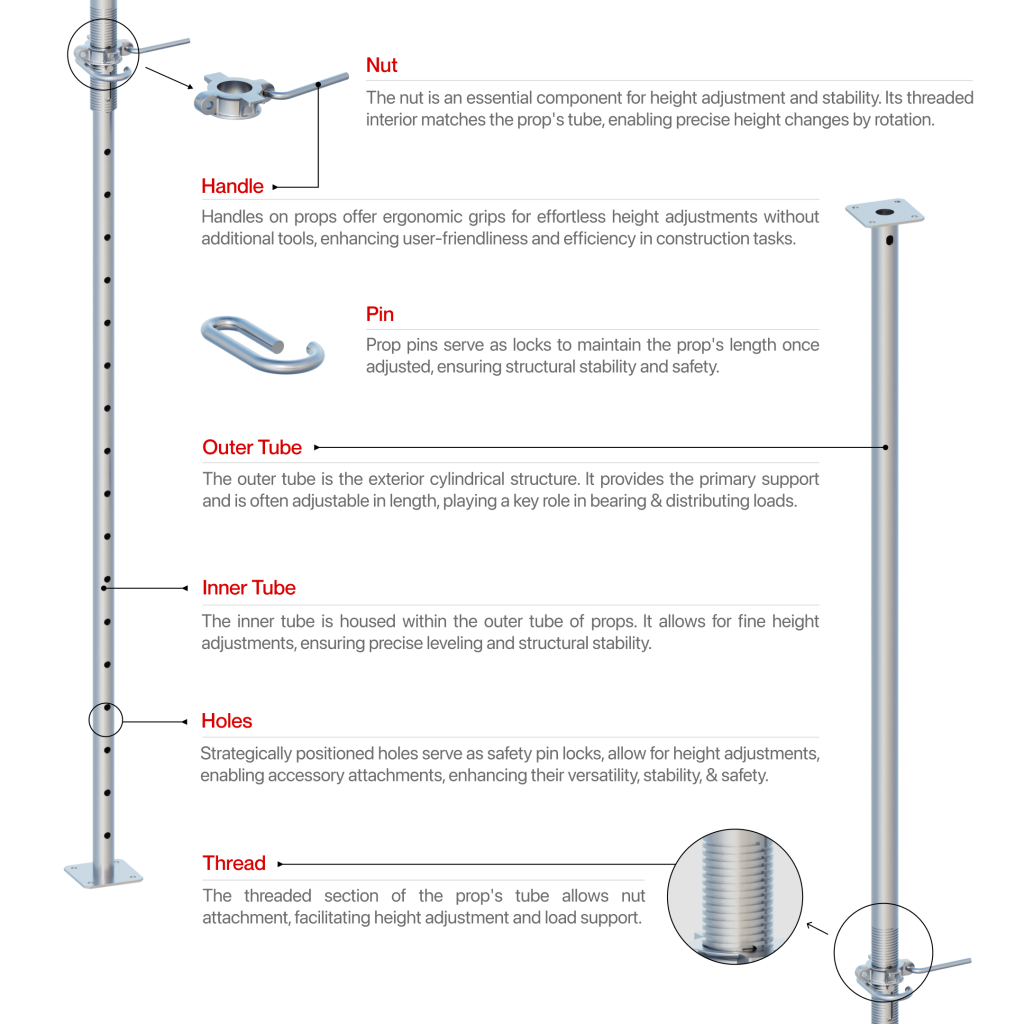

Components of Props

Process and Machinery Involved

Raw Material Selection After receiving an order, our technical department meticulously selects the appropriate raw material based on the specific prop requirements. The chosen raw material undergoes a rigorous quality assessment conducted by our dedicated quality team.

Cutting and Drilling The selected pipes are then moved to the cutting and drilling phase. With the aid of our state-of-the-art Laser pipe cutting machine, we achieve precise, clear cuts on both the internal and external pipes, maintaining a tolerance of ±1mm. Thanks to cutting-edge technology, the drilling process is rapid, accurate, and free of burrs.

Threading and Welding Subsequently, the pipes advance to the threading and welding stage. Our threading machine is capable of threading steel pipes with diameters ranging from 38mm to 90mm. We offer customization of the machine according to customer specifications, accommodating both 3TPI and 4TPI threading requirements.

Galvanization or Powder Coating Process Following welding, the props proceed to the galvanization or powder coating process. Hot-dip galvanization is chosen for enhanced durability, rendering the props suitable for all environments while withstanding external atmospheric elements. Our selection of galvanization method and specifications is tailored to meet individual customer preferences and needs.

Advantages of Allmarc Props

- On-time delivery for uninterrupted construction confidence. - Balancing cost and quality in every prop we offer. - Galvanized props for enduring, corrosion-free construction. - Highest quality control and quality checks of raw material and dimensions. - Lab testing and reports on request. - Better salvage value at the end of the useful life.

Additional Accessories

Props Extension Props Extension components are crucial in construction projects where varying height requirements are essential. These extensions seamlessly integrate with standard props, allowing for an extended height range. This adaptability is particularly useful in formwork scenarios where diverse construction needs demand flexible and reliable vertical support.

Prop Head The Prop Head is the pinnacle of stability in formwork construction. Placed atop props, it provides a secure foundation for beams and formwork structures. Its design prioritizes stability, ensuring the structural integrity of vertical elements in construction projects.

U Head U Head components exhibit a unique design, forming a U-shaped support structure that excels in securely holding beams within formwork systems. This design not only enhances stability but also streamlines the placement of beams, contributing to efficient and reliable construction practices.

4 Way Head / Cross Head The 4 Way Head, or Cross Head, is a versatile component designed to offer multi-directional support for beams within formwork. Its adaptability allows for a wide range of applications, ensuring robust support in diverse construction scenarios where flexibility is paramount.

Birch Ply Birch Ply stands as a high-quality plywood variant crafted from durable birch wood. Recognized for its strength and versatility, Birch Ply is a trusted material in construction and formwork applications. Its sturdy composition makes it an ideal choice for various construction needs, ensuring reliability and longevity in projects of diverse scales.

Customisations Feasible

Our team of experienced engineers excels in fabricating bespoke solutions tailored to your specific requirements. From intricate details to large-scale projects, we ensure precision and excellence in every customization. Your vision, our expertise – let's build success together.

Request a Quote

Obtain an estimate for your project needs with Allmarc. Our team is ready to provide accurate and tailored cost assessments to help you plan and execute your construction projects efficiently. Please share your inquiry on sales@allmarcindia.com or fill up the below contact form - our sales executive will connect with you within 24 hours.

Get in touch.

Feel free to reach out for inquiries or more information.