Allwell Deep Foundation

The Allwell Deep Foundation is a robust and innovative solution, featuring large-diameter excavation and grouting to enhance soil stabilization.

Overview of Allwell Deep Foundation

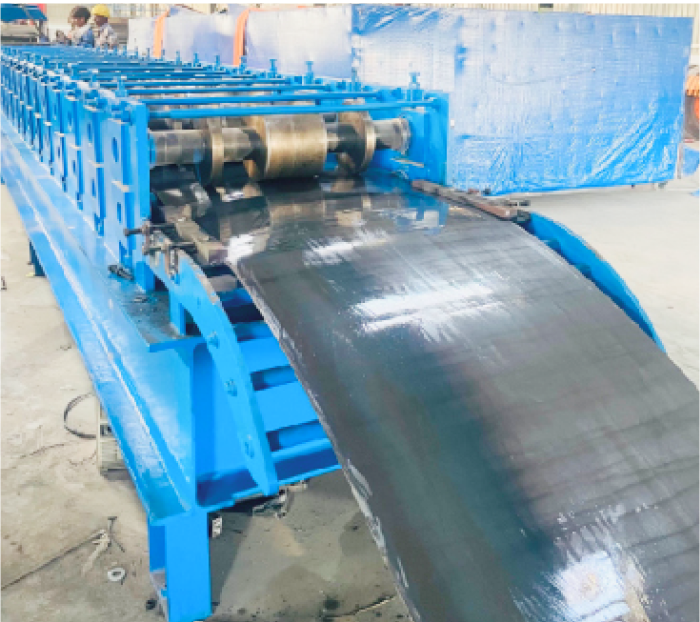

Allmarc takes pride in offering the Allwell Deep Foundation, an advanced and highly effective solution tailored for large-diameter excavations, ranging from 6 meters to 11 meters. This is achieved through the strategic placement of corrugated steel liner plates in a circular formwork configuration, providing substantial support to the bore wall. The annular space between these plates and the surrounding soil undergoes meticulous grouting, ensuring enhanced soil stabilization. To facilitate the manufacturing process, Allmarc has engineered a specialized Roll Forming Machine designed for crafting these liner plates. This machine possesses the capabilities of forming, punching, and cutting at the center, streamlining the production of these critical components. The Allwell Deep Foundation stands out with various innovative features. These include a top guide frame for precise alignment, a ladder provision for easy access, a collapsible roof offering protection during the rainy season, and a reinforcement fixing jig for cage lowering. These features collectively contribute to making the Allwell Deep Foundation an exceptional solution for demanding excavation projects. Moreover, it's worth mentioning that Allmarc's Allwell Deep Foundation has received approval from NHRCL (National High-Speed Rail Corporation Limited), attesting to its compliance with industry standards and recognizing its effectiveness in protecting railway line foundations.

Benefits of Allwell Deep Foundation

- Large-Diameter Excavation - Enhanced Soil Stabilization - Advanced Roll Forming Machine - Innovative Design Features

Uses of Allwell Deep Foundation

Allmarc's Allwell Deep Foundation is specifically designed for use in urban areas and locations adjacent to railway lines. Its primary purpose is to safeguard the foundation of railway lines from vibrations and potential collapse, a critical consideration in city areas where minimizing impact on the surroundings is paramount. The utilization of Allwell Deep Foundation streamlines excavation processes in urban settings by reducing the required diameter, minimizing the risk of damage to nearby structures or buildings.

Features of Allwell Deep Foundation

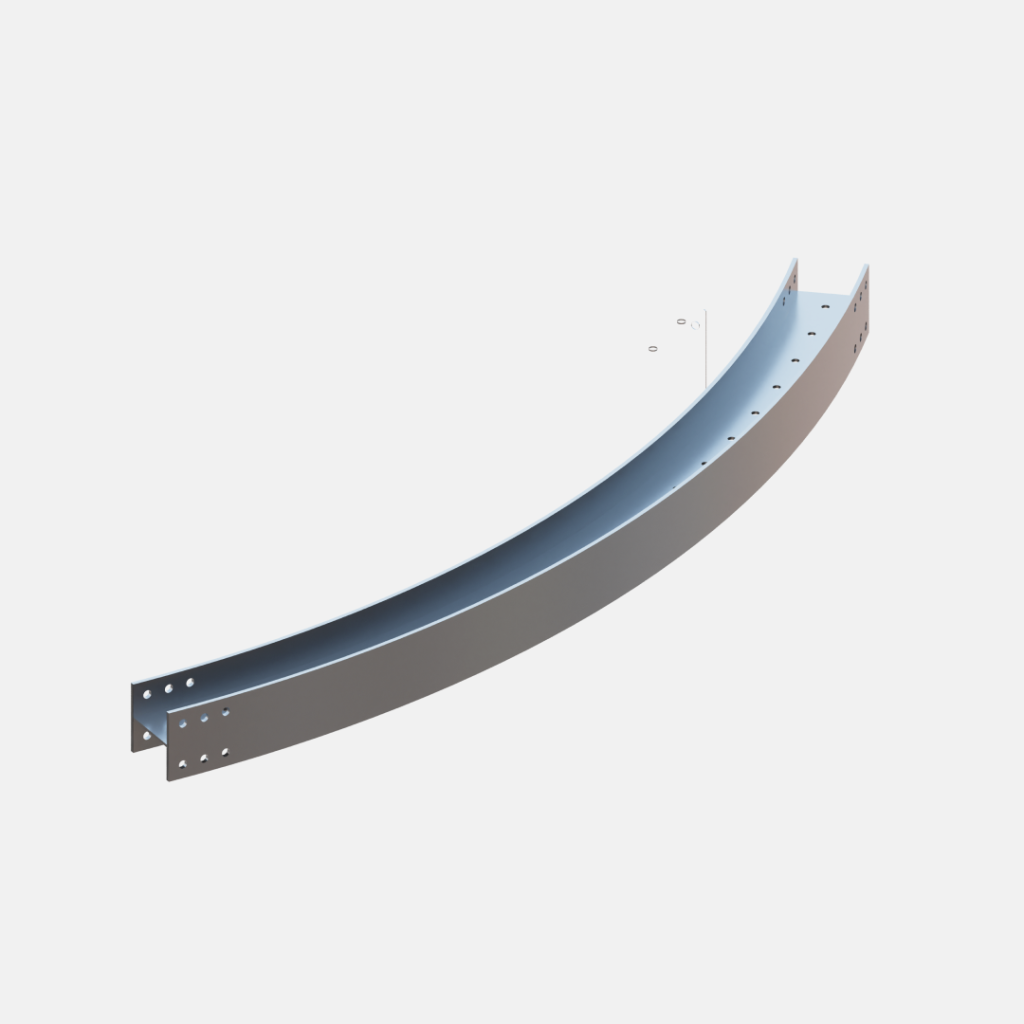

Curve Beam

Curve beam typically represents a beam or structural element with a curved or arched shape. These beams are designed to provide support and strength to the deep foundation, contributing to its stability and load-bearing capacity.

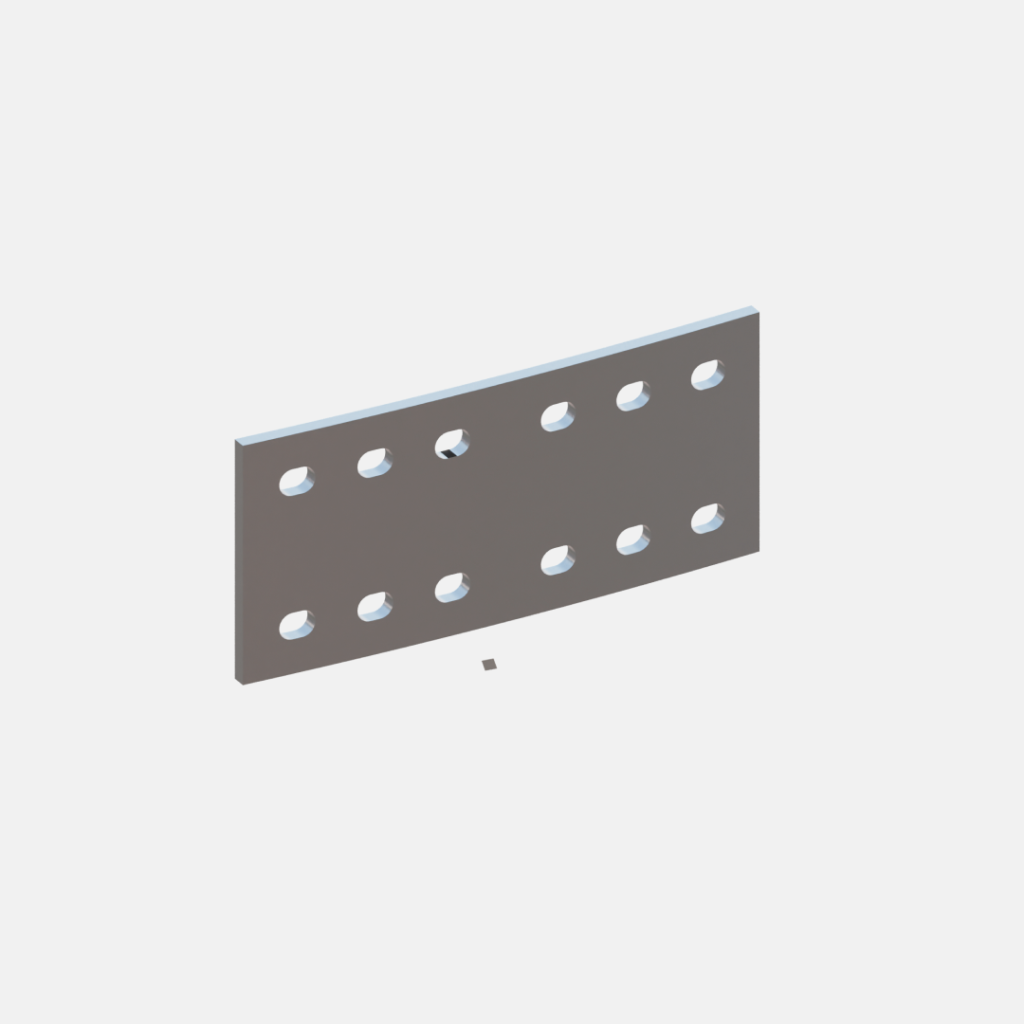

Fixing Plate

Fixing Plate is a component used to secure or fasten structural elements together. These plates serve to connect various components of the deep foundation system, ensuring stability and structural integrity.

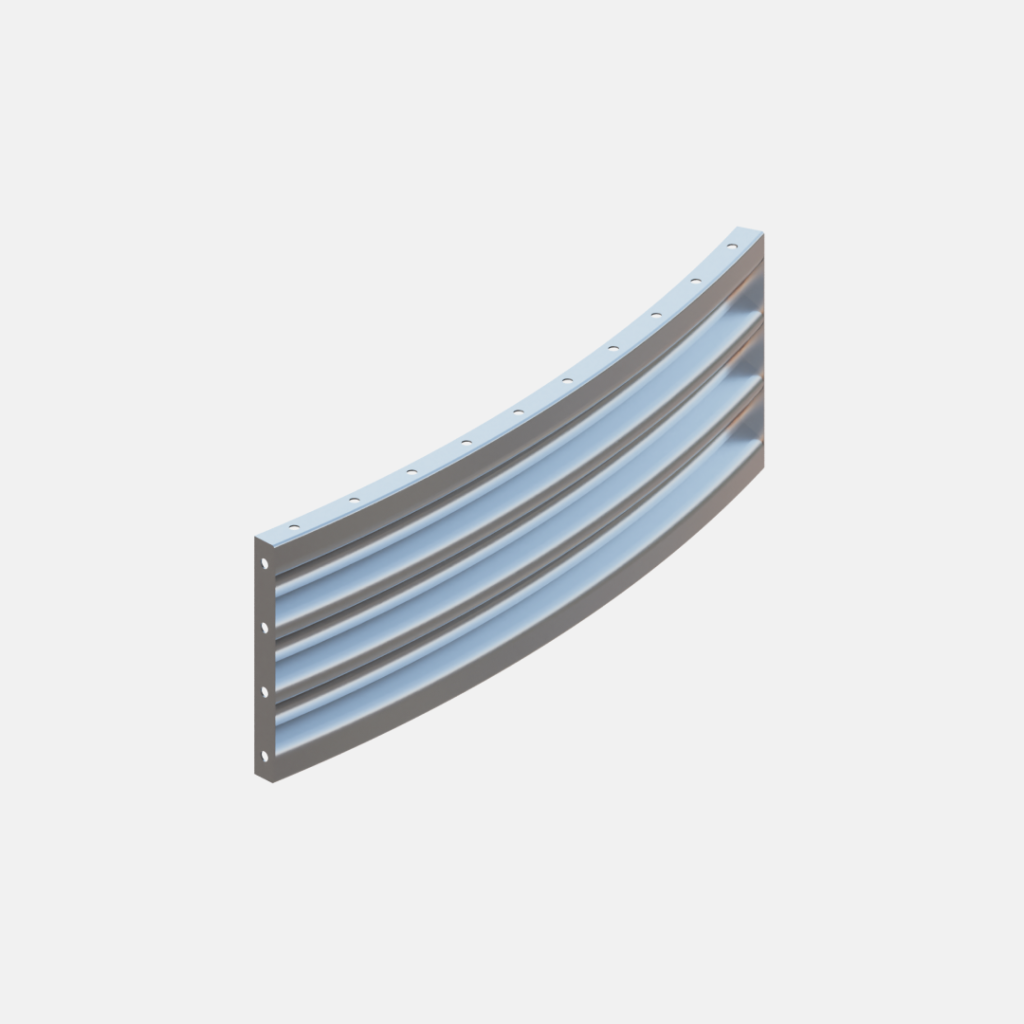

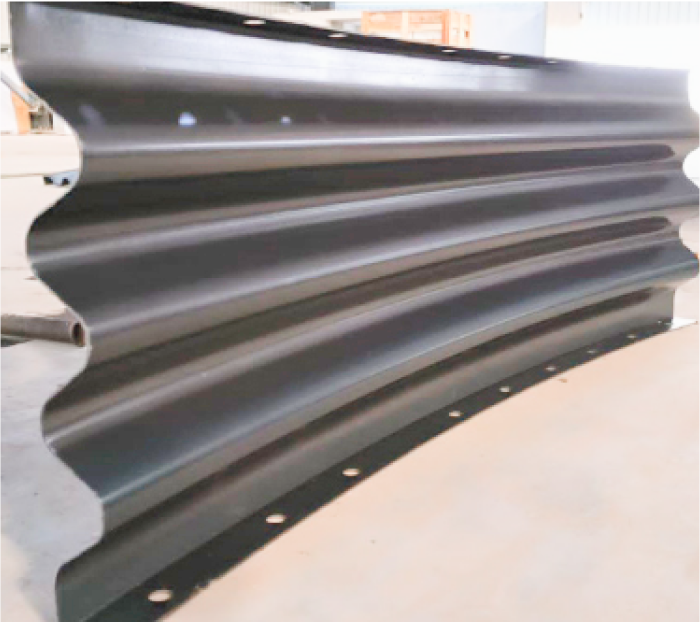

Liner Plate

Liner plate refers to a steel plate used to reinforce and protect the bore walls during excavation. These plates are corrugated and placed inside the bored hole to maintain its structural integrity and prevent soil collapse during the drilling process.

Additional Features of Allwell Deep Foundation

- Alignment and Positioning: The top guide frame ensures precise alignment and positioning. - Manpower Accessibility: A ladder provision allows easy access for workers. - Weather Protection: A collapsible roof safeguards the well during the rainy season. - Efficient Cage Lowering: A reinforcement fixing jig aids in the efficient lowering of the cage.

Manufacturing Process

Raw Material Inward & MIR

Gauging by Sensors

Forming with roll forming machine

Cutting by Automated Hydraulic Shear Press

Hole Punching

Liner Sheet with end plate and Curve Beam (forming shape)

Curving: 6 to 11 mtr dia.

End Plate Welding by Robot

Customisations Feasible

Our team of experienced engineers excels in fabricating bespoke solutions tailored to your specific requirements. From intricate details to large-scale projects, we ensure precision and excellence in every customization. Your vision, our expertise – let's build success together.

Request a Quote

Obtain an estimate for your project needs with Allmarc. Our team is ready to provide accurate and tailored cost assessments to help you plan and execute your construction projects efficiently. Please share your inquiry on sales@allmarcindia.com or fill up the below contact form - our sales executive will connect with you within 24 hours.

Get in touch.

Feel free to reach out for inquiries or more information.