Allshore Shoring System

Heavy-Duty Ring Lock System

Heavy-Duty Ring Lock System: Elevating Construction Stability

The Heavy-Duty Ring Lock System stands as a robust solution engineered to meet the demands of heavyweight construction projects. With an impressive load capacity of 8 metric tons, this system provides unparalleled stability, ensuring a secure foundation for intricate structures. Its design accommodates pipes with diameters of up to 65 mm, further enhancing stability and load-bearing capabilities. The streamlined spring locking system not only simplifies assembly processes but also prioritizes efficiency and job site safety.

Key Features of Ring Lock System

Exceptional Load Capacity

With an impressive 8 MT load capacity per leg, these systems offer unwavering support for substantial construction projects.

Crafted for Dependability

Constructed to endure the rigors of construction environments, these systems are engineered for long-lasting performance.

Rock-Solid Stability

Boasting a sturdy 65 mm diameter, these systems ensure superior strength, providing a solid foundation for secure structures.

Versatility Unleashed

Mastering a broad spectrum of high-load shoring tasks, these systems are your versatile construction solution.

Effortless Assembly

Our innovative ring locking system simplifies and expedites the assembly process while ensuring maximum job site safety.

Safety as a Priority

Designed with a strong focus on safety, these systems guarantee stable and secure structures for your construction projects.

Application of Ring Lock System

Ring Lock systems serve vital roles in construction, ensuring support, stability, and safety across project.

Supporting Formwork

Shoring systems ensure safe concrete placement by supporting formwork during construction.

Building Construction

Essential for structural stability, shoring systems support beams, floors, and roofs temporarily.

Bridge Construction

Vital in bridge deck construction, shoring systems maintain structural integrity during assembly.

Tunneling

Prevent collapses in tunneling by supporting walls with reliable shoring systems.

Excavations

Shoring prevents soil collapse, ensuring worker safety during deep excavations for basements.

Demolition

Safely support building elements during demolition using shoring systems for controlled dismantling.

Emergency Situations

Stabilize damaged structures in emergencies, preventing further collapse with reliable shoring systems.

Custom Applications

Tailored shoring systems adapt to diverse construction tasks, ensuring project-specific support and safety.

Introducing Allshore Shoring System

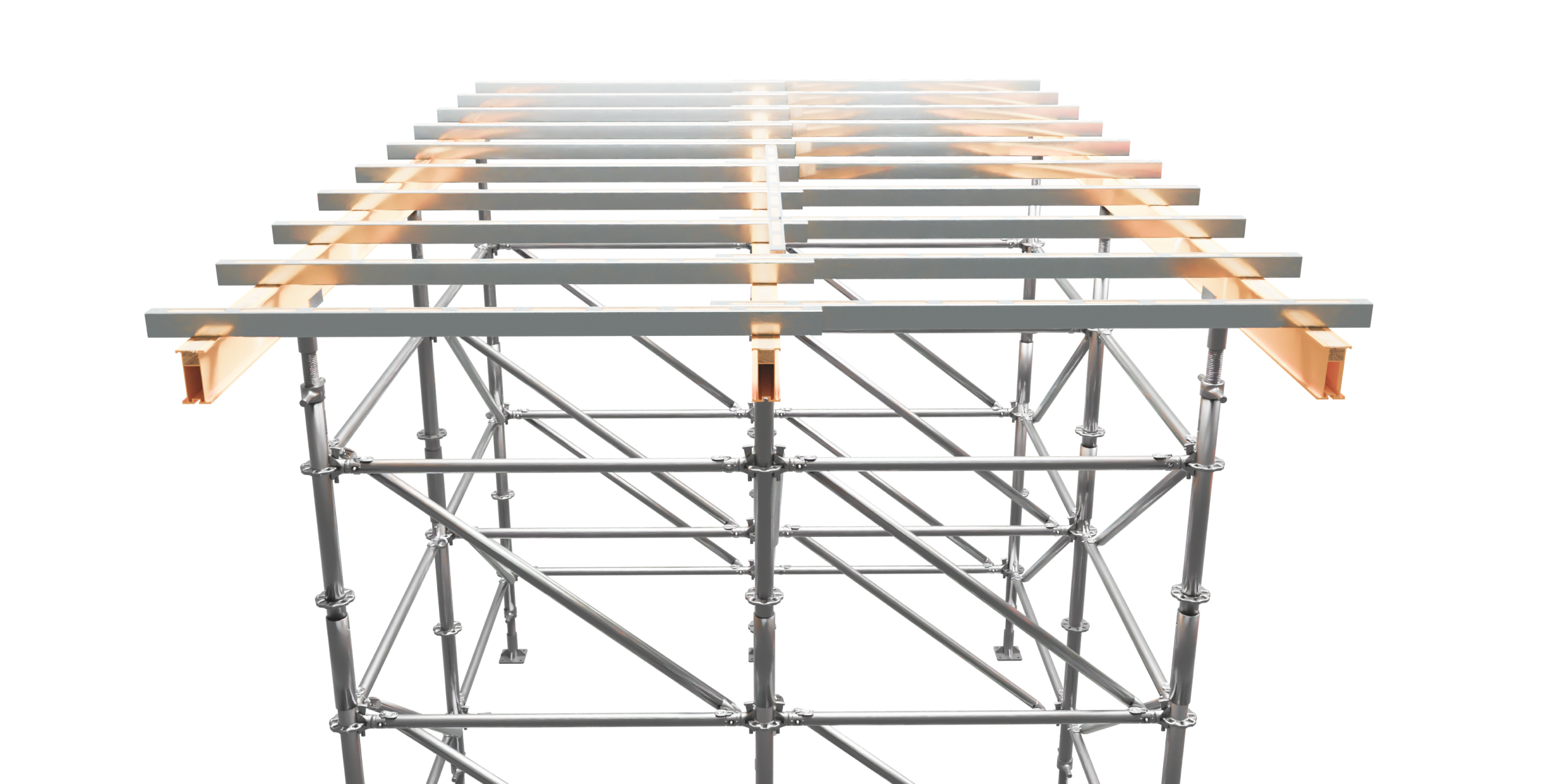

Allshore Shoring Systems are engineered to provide support and stability to structures, especially in excavation sites or during construction activities where load-bearing capacity is critical. They are specifically designed to bear heavy loads and prevent collapses.

Key Features

Allshore system prioritize load-bearing capacity, structural stability, and safety. They often include components like vertical supports, horizontal braces, and systems to prevent soil collapse during excavation.

Common Use

Allshore system find applications in construction sites where there's a need to support existing structures, prevent soil movement, or ensure the stability of temporary structures during construction.

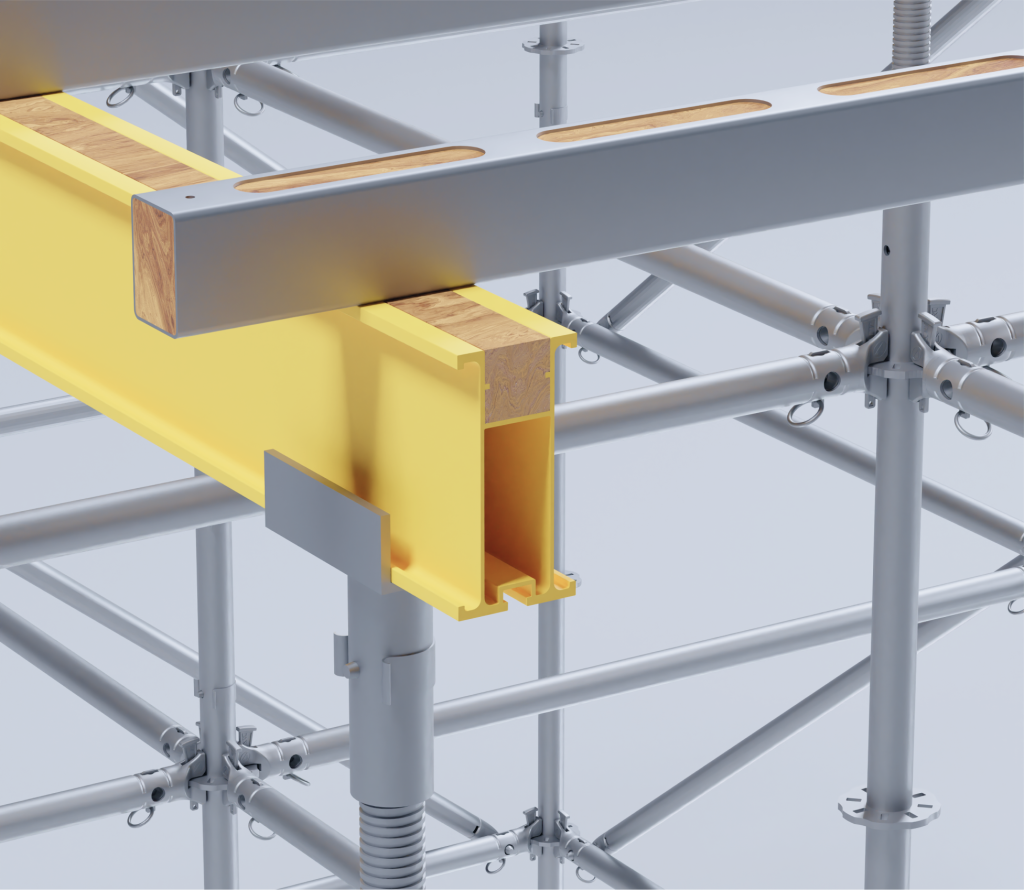

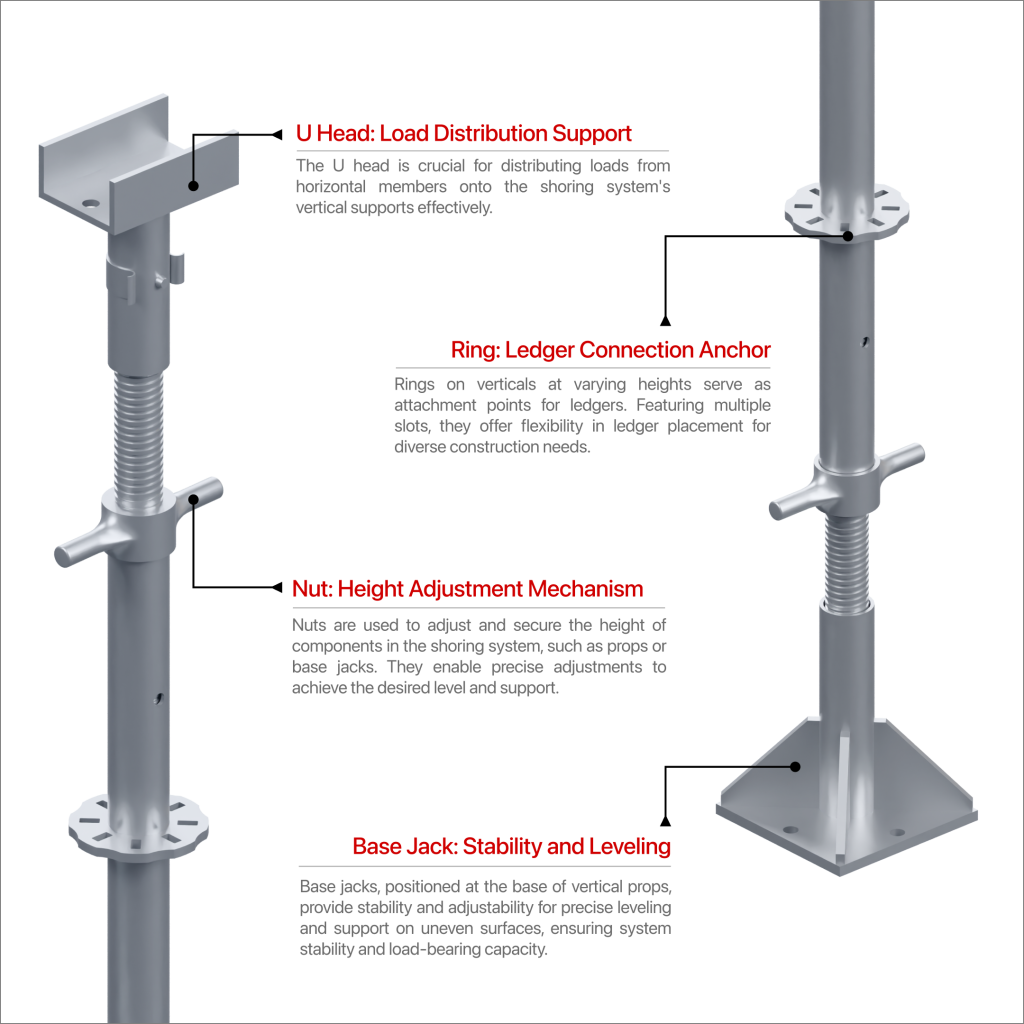

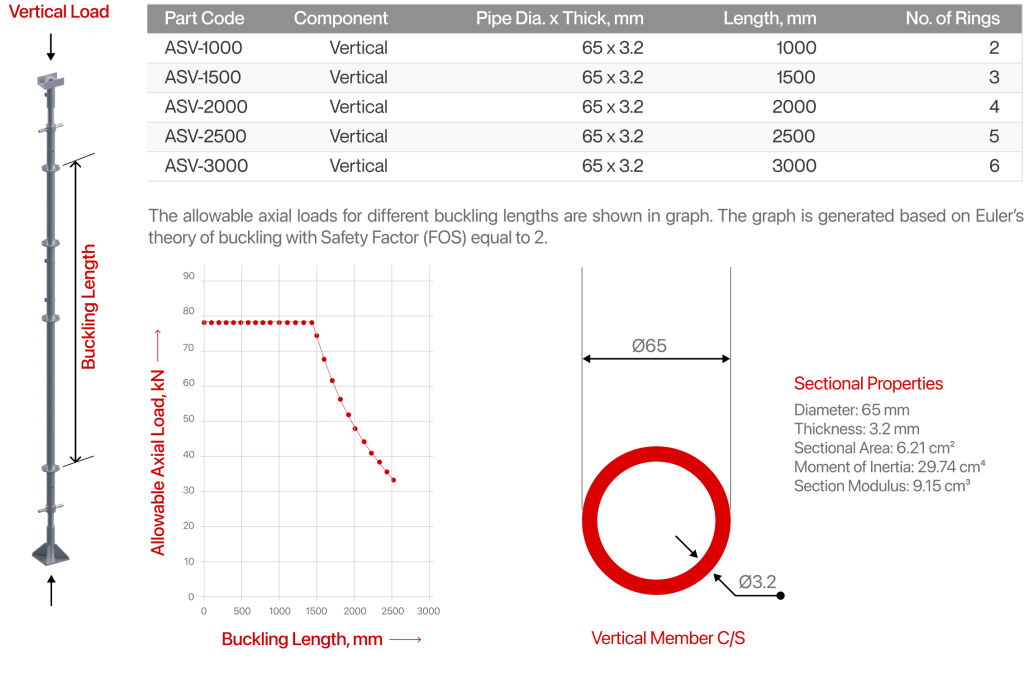

Verticals for Allshore Shoring System

The Verticals are main members in shoring system to take vertical load directly. They are made from the highest quality steel with welded Rosset plates at the pitch of 500mm. The cutouts in Rosset plate are done by using precision Laser Cut operations. Rosset plates are welded by robotic welding process to get consistency in welding and dimensional accuracy.

Verticals Specifications for Allshore Shoring System

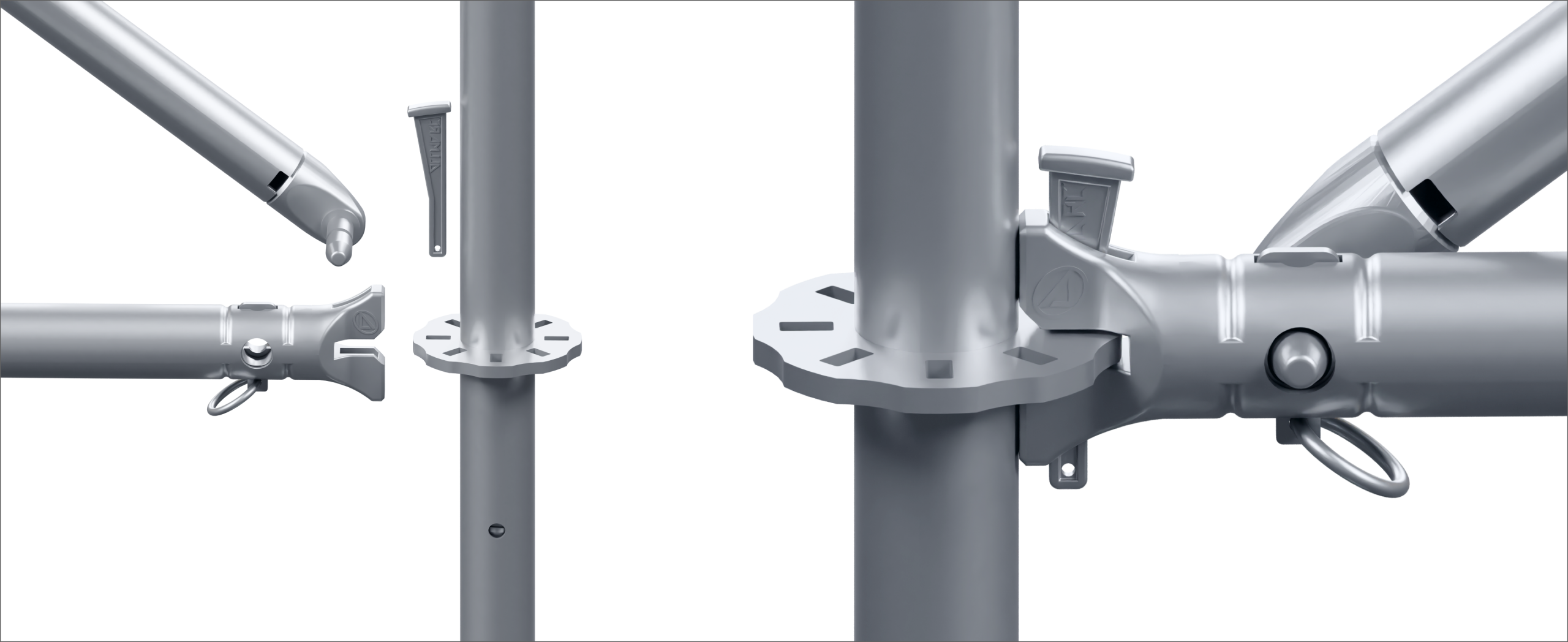

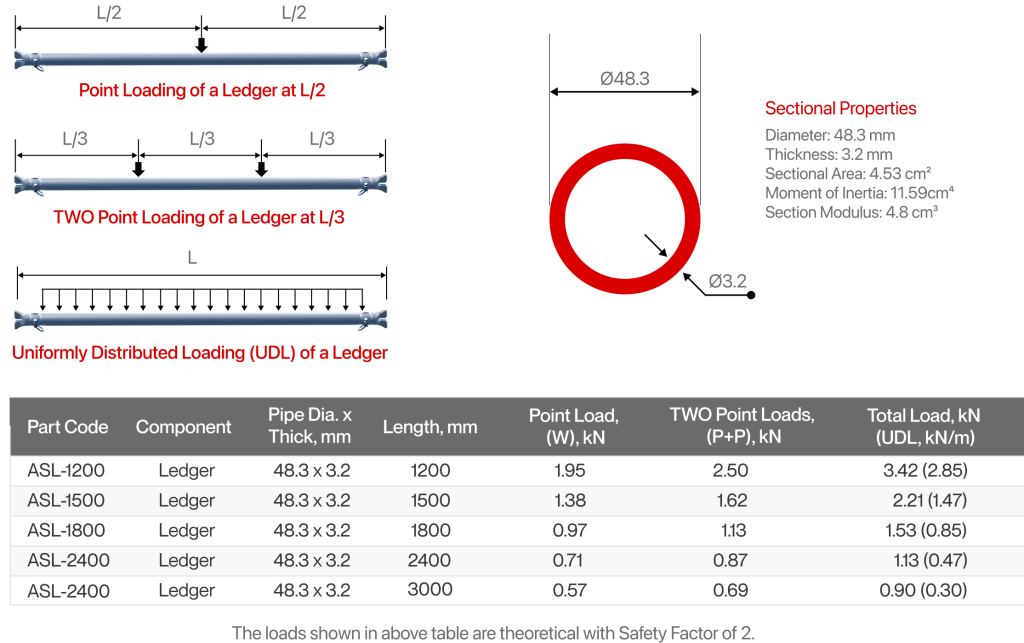

Ledgers for Allshore Shoring System

The Ledgers are horizontal members in shoring system to take horizontal loads directly transmitting along the member axis. Ledgers also carry lateral loads (i.e. vertical downward or upward load due to planks and walkways). They are made from the highest quality steel by crimping pipe with investment casted End connectors. Ledgers are assembled to vertical via Rosset plate and End Connectors fitted with a wedge. Ledger has in built locking mechanism at both the ends to lock Bracings (diagonal members) The allowable Lateral loads for different lengths are shown in table below.

Specifications of Ledgers for Allshore Shoring System

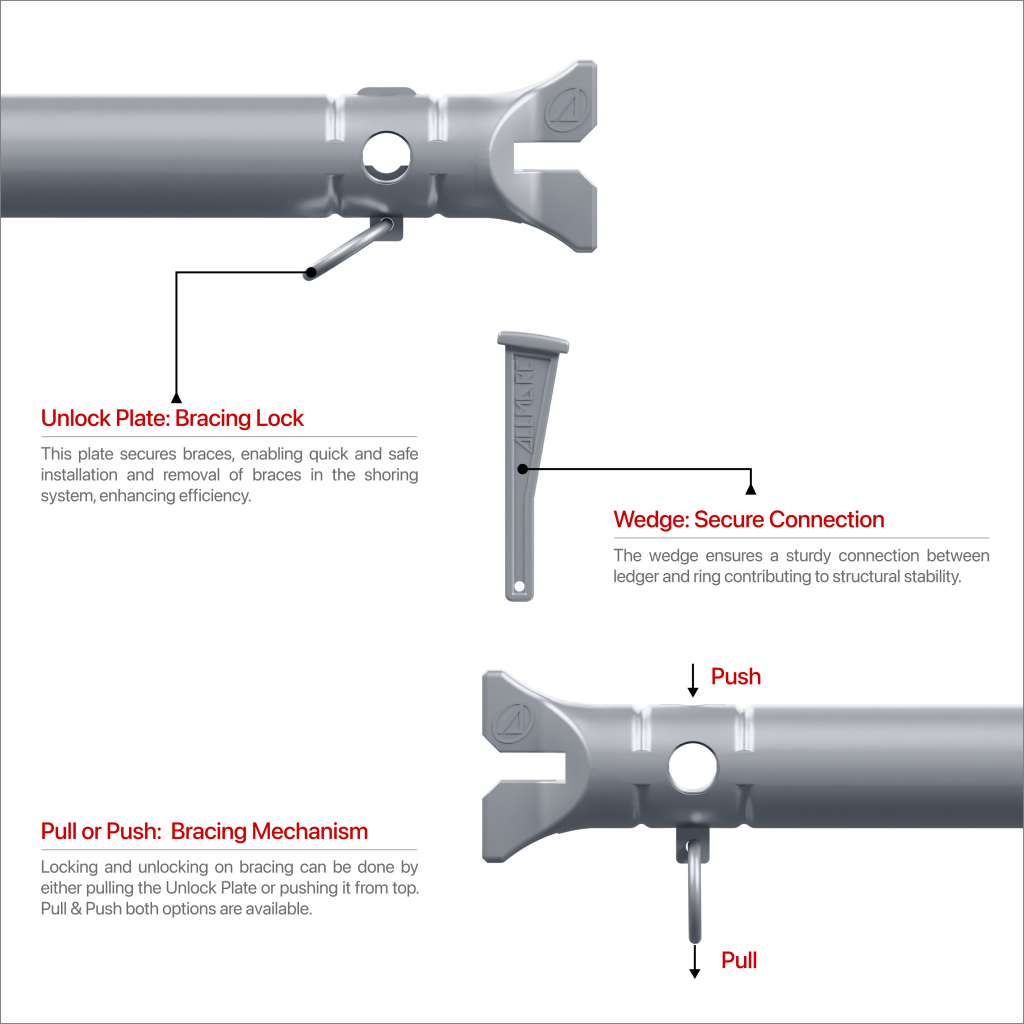

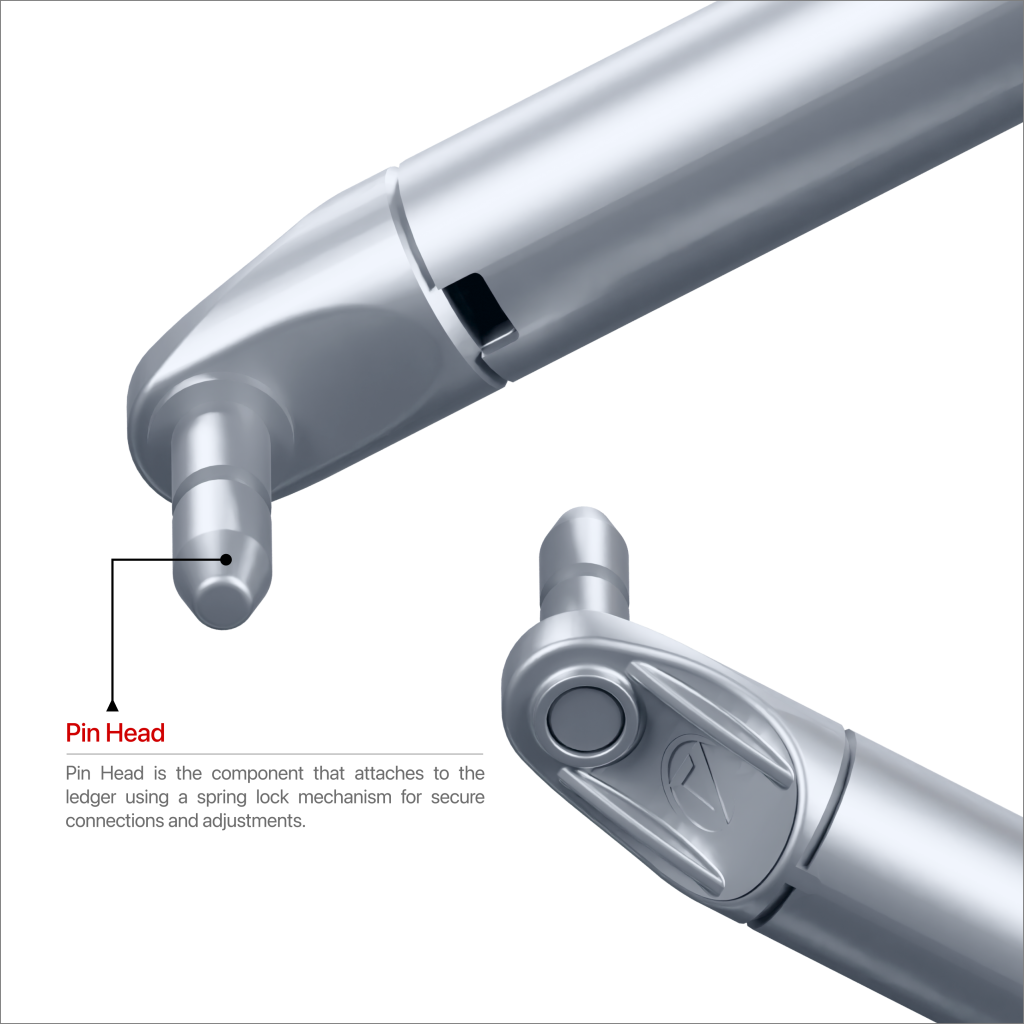

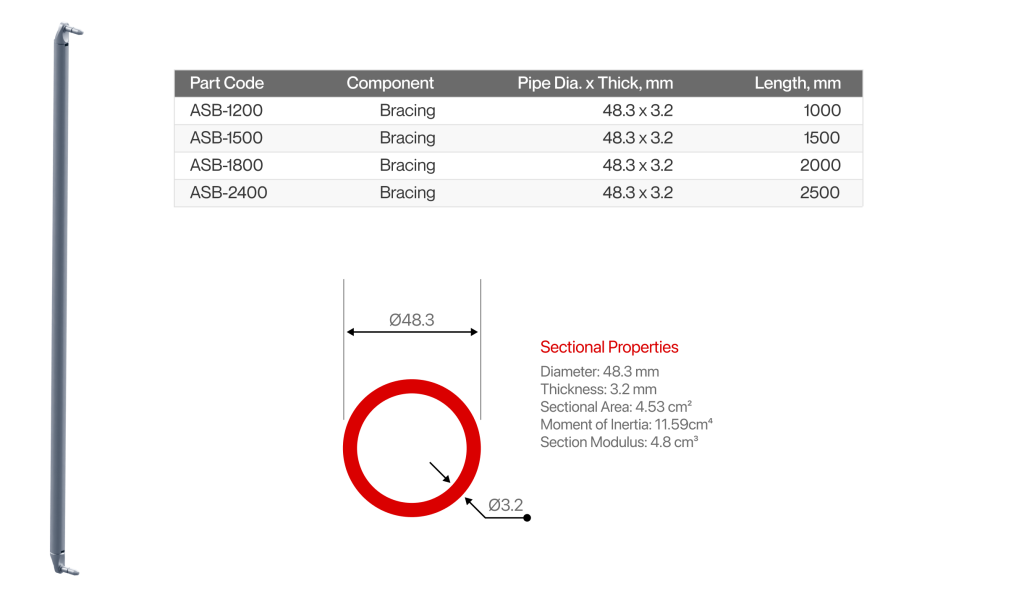

Bracings for Allshore Shoring System

The Bracings are diagonal members in shoring system to take inclined loads directly transmitting along the member axis which is along the diagonal. They are made from the highest quality steel by welding pipe with investment casted End connectors. Bracings are assembled to Ledgers via end cylindrical pin which is locked by spring loaded locking plate present in Ledgers. Bracings can be dismantled by either pull or push of locking plate. Ledger has in built locking mechanism at both the ends to lock Bracings (diagonal members)

Specifications of Bracings for Allshore Shoring System

Customisations Feasible

Our team of experienced engineers excels in fabricating bespoke solutions tailored to your specific requirements. From intricate details to large-scale projects, we ensure precision and excellence in every customization. Your vision, our expertise – let's build success together.

Request a Quote

Obtain an estimate for your project needs with Allmarc. Our team is ready to provide accurate and tailored cost assessments to help you plan and execute your construction projects efficiently. Please share your inquiry on sales@allmarcindia.com or fill up the below contact form - our sales executive will connect with you within 24 hours.

Get in touch.

Feel free to reach out for inquiries or more information.